Dolomite Powder Making Machine with Large Capacity for Other Non-Metallic Deposits Perlite Sepiolite Silica Talc Vermiculite Wollastonite Powder Production Line

Product Overview Grinding Mill Equipment : - - Five models: HGM80, HGM90, HGM100, HGM100A, and HGM125 - - Finished produ;

Basic Info

| Model NO. | HGM |

| Condition | New |

| Warranty | 1 Year |

| After-sales Service | Technical Support |

| Outlet Size L*W*H (M) | 18*4.6*8.6 |

| Finished Size (Um/Mesh) | 150-2500 |

| Input Size (mm) | Less Than 20 |

| Ring Diameter(mm) | 1000 |

| Ring Number (PCS) | 4 |

| Roller Number(PCS) | 30-44 |

| Main Shaft Speed (R. P. Min) | Main Shaft Speed (R. P. Min) |

| Transport Package | Standard, Container Needed |

| Specification | CE, SGS |

| Trademark | Clirik |

| Origin | Shanghai, China |

| HS Code | 84742090 |

| Production Capacity | 1000 Sets Per Year |

Product Description

Product OverviewGrinding Mill Equipment :

- - Five models: HGM80, HGM90, HGM100, HGM100A, and HGM125

- - Finished production fineness: 300meshes~3000meshes, 5-47 micron

- - The capacity (ton/hour) ranges from 0.4T/H to 12T/H

Parameter Grinding Mill Equipment :

Parameter 1

| Model | HGM80 | HGM90L | HGM100L-II HGM100P | HGM125L | HGM168L |

| Ring Diameter(mm) | 800 | 900 | 1000 | 1250 | 1680 |

| Ring Number(PCS) | 3 | 3 | 4 | 4 | 4 |

| Roller Number(PCS) | 18-21 | 24-29 | 28-36 | 30-40 | 30-44 |

| Main Shaft Speed(r. p. min) | 230-240 | 200-220 | 180-200 | 135-155 | 120-130 |

| Input Size(mm) | ≤20 | ≤20 | ≤20 | ≤20 | ≤20 |

| Finished Size(um/mesh) | 74-5(200-2500) | 74-5(200-2500) | 74-5(200-2500) | 100-8(150-2000) | 100-9(150-1500) |

| Capacity(t/h) | 0.5-5.5 | 0.8-6.5 | 1.2-101.2-11 | 2.5-20 | 5-45 |

| Outlet Size L*W*H(m) | 15.1*4.2*7.3 | 18.4*3.9*7.8 | 22.7*3.6*8.5 | 27.3*4.2*9.9 | 31.7*7.7*12.6 |

| Note:The capacity is based on the domesitlc CaCO3 Powder factory's feedbackNote:The capacity is based on the domesitlc CaCO3 Powder factory's feedback | |||||

| Unit KW | HGM80 | HGM90L | HGM100L-II HGM100P | HGM125L | HGM168L |

| Main Unit | 75 | 2*45 | 132-150 | 185-200 | 315 |

| Classifier | 18.5 | 18.5-30 | 30-37 | 75 | 132 |

| Blower | 45 | 55 | 75 | 2*45-2*55 | 2*75-2*90 |

| Crusher | 18.5 | 18.5 | 18.5 | 45 | 75 |

| Bucket Elevator | 3 | 3 | 4 | 4 | 7.5 |

| BeltConveyor Feeder | 1.5 | 1.5 | 1.5 | 1.5 | 2.2 |

| Discharging Valve | 2*0.75 | 1.1 | 1.1 | 1.5 | 2*1.5 |

| Air compressor | 11 | 15 | 22 | 37 | 55 |

| Note:For the data with prefix such ad "2xx",which means there are two same motors configured for one item | |||||

Application of Grinding Mill Equipment :

HGM Series Blast Furnace Slag GGBS/GGBFS/GBFS grinding mill is the equipment specializing in producing fine and superfine powder of non-inflammable, non-explosive and brittle materials with Moh's hardness under six, such as calcite, chalk, limestone, dolomite, kaolin, bentonite, talc, mica, magnesite, illite, pyrophyllite and vermiculite, sepiolite, attapulgite, rectorite, diatomite, barite, gypsum, alunite, graphite, fluorite, rockphosphate, Kalium ore, pumice, etc., totally more than 100 kinds of materials.

Work Principle of Grinding Mill Equipment :

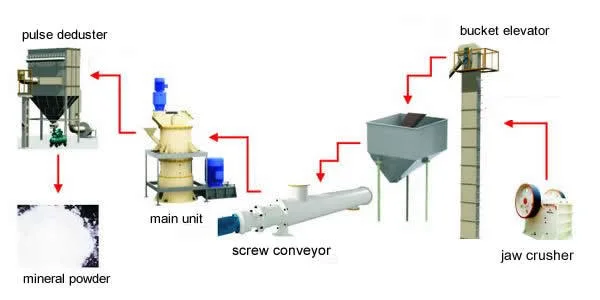

HGM series Blast Furnace Slag GGBS/GGBFS/GBFS grinding millmainly consist of main unit, classifier, powder collector, dust cleaner, blower, muffler, sound-proof room, crusher, bucket elevator, storage hopper, and vibrating feeder.

Videos of Work Principle:

https://shclirik.en.made-in-china.com

https://shclirik.en.made-in-china.com

Features of Grinding Mill Equipment :

1.High Efficiency

Under the same finished final size and the same motor power, the capacity of Blast Furnace Slag GGBS/GGBFS/GBFS grinding mill is twice as much as jet mill, mixing grinder and ball mill, and energy consumption decreased 30%.

2.Long lifecycle of spare parts

The ring and roller are forged by special material with high utilization, the lifetime can reach 2-5 years for grinding calcite carbonate.

3.High safety and reliability

As no rolling bearings or screws in grinding cavity, there are no problems caused by bolts shedding or rapid wear of bearings and seal components.

4.High fineness, flexible adjustment

The final fineness of the grinding materials can be adjusted between 325 meshes and 2500 mesh (47-5 micron), and the product fineness can reach D97≤ 5μ M.

5.Environment-friendly

The application of pulse bag filter and muffler greatly alleviates dust pollution and noise.

Advanced intelligent speed control device

Convenient adjusting, more uniform particle size.

Other Products offered

Company Profile

Our Company

Shanghai Clirik Machinery. The main products of the company are HGM series ultrafine mill, YGM series high pressure hanging roller mill,SLG series micro-powder modification machine, etc. It is engaged in the research and development, production of ore micro-powder equipment, ore micro-powder technology research and application enterprises.

20 Years

Specialized in ultrafine powder equipment R&D and manufacturing for more than 20 years.

120 Square

The total production area more than 1,200,000 m², one of the biggest grinding mills manufacturers in China.

150 countries

Our grinding mills are exported to more than 150 countries and regions in Eastern Europe, Middle East, Africa, Australia, America, etc.

100 People

More than 100 after-sales technicians are ready for service to you no matter what time it is.

Our Certification

Our Services

1.One year guarantee for whole machine except for wear parts.

2.24 hours technical support by email.

3.Calling service.

4.User manual available.

5.Reminding for the service life of the wearing parts.

6.Installation guide for clients from both China and abroad.

7.Maintance and replacement service.

8.Whole process trainling and guidance from our technicians.

High quality of after-sales service symbolizes our brand and ability. We pursue not only good quality products, but also best after sales service. Your satisfaction is our final purpose.

FAQ

Because there 5 different kinds of ultrafine grinding mills, so our HGM series grinding mill unit has different prices, I need to ask you some details for sending you the more suitable quotation:

1.Which kind of material you are going to grinding?

(Dolomite; Calcite; Quartz; Basalt; Barite; Feldspar ; Gravel; Bentonite; Gypsum; Granite; Coal; Slag; Pebble; Others )

2. What's the production capacity you want? How many tons or cubic meters per hour?

( > 100 TPH > 50 TPH > 30 TPH > 10 TPH > 1 TPH < 1 TPH)

3.What's the granularity of the final products you need?

(in milimeter, micron or mesh)

4. What's the max input size of the material?

(In inch,centimeter or milimeter)

We will give you factory price with full specification,so pls leave us an inquiry to know more details about price, packaging

shipping and discount.

You may also like

Send inquiry

Send now