GBHW-625 Fully Automatic Edge Cutting Machine

Basic Info

| Model NO. | GBHW-800 |

| Control | Artificial |

| No. of Blades | 1 |

| Power | 18.5kw |

| Weight | 6000kg |

| Worktable Rotating | 90 or 360 |

| Max.Cutting Size | 3200X2000mm |

| Blade Tilting Angle | 45 Degree |

| Blade Diameter | 600/800mm |

| Transport Package | Nude Packing |

| Specification | 5870x4700x2700 |

| Trademark | Great Base |

| Origin | Xiamen, Fujian, China |

| HS Code | 84641090 |

| Production Capacity | 100pieces/Month |

Product Description

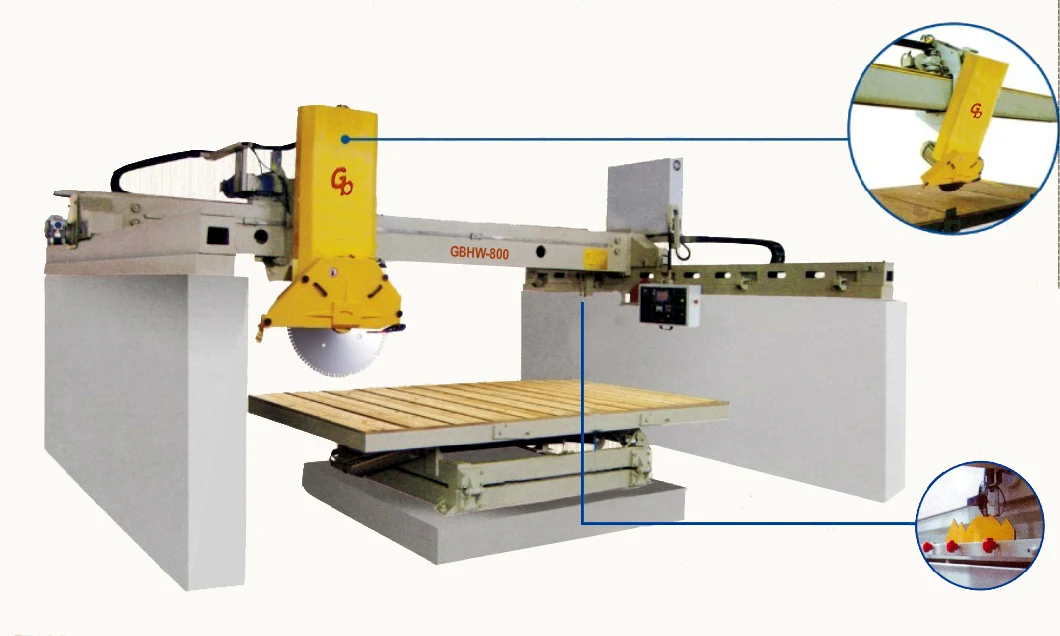

GBHW-800 Automatic Bridge Saw is a highly automatic machine well built to perform various tasks in marble and granite processing. It is unique in our bridge saw family that its motor drives blade directly in the same spindle and its blade can tilt 0˚-45˚ for chamfering cutting.

The bridge of this bridge sawing machine has been built in large thickness normalized cast iron. Cast iron can give the bridge high level rigidity and prevent it from shape deformation. Two V-shaped tracks have been machined on the bridge top with small clearance to guide blade holder movement. The blade holder moving tracks are oil-bathed and covered by organ shield after installation.

The bridge sawing machine blade lifting/lowering movement is driven by one lead screw and guided by two chrome-plated steel columns. The lead screw is put in the middle of the two steel columns to keep balance in driving force. The blade holder is designed to have two parts for blade tilting purpose. The inner part in contact with the bridge is responsible for blade X-axis movement. The outer part is attached to the inner part and be able to turn clockwise or counter-clockwise.

There are two pieces bridge moving track installed on concrete foundation to ensure the bridge saws vibration free. High precision linear guides have been used in the bridge moving tracks to achieve smooth movement and precise positioning. The bridge moving tracks are also oil-bathed and covered to be protected from dust and water spray.

In the right end of the bridge sawing machine are electric cabinet and control panel with LCD display. The heart of this machine such as PLC and convertors are installed inside the electric cabinet. Parameters can be put into the machine on the control panel, then the bridge sawing machine start to do automatic sawing under the control of its PLC system. Frequency converter is also used in the bridge saw machine for different blade running speed.

Bridge sawing machine worktable is constructed in size 3200mm long and 2000mm wide. It can tilt 85 degree for easy slab loading/unloading and rotate 90 degree for easy cutting of all four sides of a slab. Both of tilting and rotating actions are powered by hydraulic.

All the metal parts of the bridge sawing machine have been sanded before assembly. When assembly is done, the cast iron bridge is inner lined with putty and have surface well painted to protect from rusting. All electric cables are supported by drag chain after machine installation at job site to ensure safety and long service life.

Common station: concrete foundation, table rotate 90 degree; We can make to order: steel structure, table rotate360 degree.

| Name | Unit | GBHW-800 |

| Blade diameter | mm | 600/800 |

| Main motor | kw | 18.5 |

| Max.cutting size | mm | 3200x2000 |

| worktable rotating | 90 or 360 | |

| Blade tilting angle | 45 degree |

NOTE:Prodiling function can be ordered

Main Features

1) Machine with competitive price and high quality ,easy in installation and maintenance.

2) Adopting advanced world famous brand components in electric parts .

3) Guarantee for one year.

Our Service

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to install the machine, training how to use the machine.

* Engineers available to service machinery overseas.

FAQ

1. Do you have more stone machines?

Yes, we can produce all series of stone processing machines with competitive price and high quality.

2. Where is your factory?

Our factory locates in Xiangbei Industry Zone,Xiang'an,Xiamen,Fujian.

3. Do you have agent?

We don't have agent as we all sell directly to our customer, in this way, the customer can get lowest cost.

4. How much is this machine?

Please tell me your stone is granite or marble, the size, your destination port, so that I can quote you best price.

5. How long can I get my product?

Normally it takes 30 days to produce our products