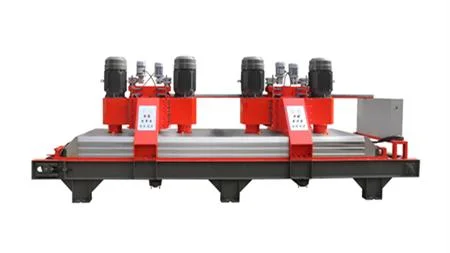

Dafon Automatic Stone Surface Edge Profiling Polishing Grinding Machine/Marble Granite Ceramic Tile Polisher Grinder Processing Equipment Manufacturer

Basic Info

| Model NO. | DFLMBJ-132614 |

| After-sales Service | Telephone Communication |

| Warranty | One Year Warranty |

| Type | Stone Grinding Machine |

| Control | Artificial |

| Automation | Automatic |

| Precision | Precision |

| Application | Ceramics, Glass, Concrete Curb, Granite, Marble |

| Type for Grinding Machine | Special Grinding Machine |

| Grinding Machine Type | Vibration Polishing Machine |

| Grinding Method | Wet Grind |

| Condition | New |

| Transport Package | Transportation in Containers |

| Specification | 8200*1400*2000mm |

| Trademark | dafon |

| Origin | China |

| Production Capacity | 120-200pieces/Year |

Product Description

| Product Description |

Automatic Super 13 heads Edge Grinding Processing machine Marble Granite

The machine has variable frequency speed regulation, automatic refueling, and maintenance, digital display after abrasive loss, which is convenient for operators to make electric compensation. 4.5kW, No. 5, 6, 7, 8, 9 motors 3kW (No. 3-9 motors stand upright, the bottom is flat and polished, the front side of the movable stone is processed with a corner line, and the edge groove is polished), the back of the No. 10 motor Cutting 7.5 kW (No. 10 motor is placed at an angle of 45 degrees, with a 300-diameter saw blade for processing slate, stone and other materials for back-cutting on the reverse side), chamfering motor, No. 11 motor 4.5 kW, No. 12, No. 13, No. 14 motor 3 kW (No. 11-14 motors are placed at an angle of 45 degrees, and the angle can be adjusted at any electric angle of 45-90 degrees to match No. 1, No. 2 forming motors to process 1/2 circle, No. 21 sides and other Roman edges), all kinds of processed stone Front chamfering, can grind the fixed thickness + right-angle bottom edge of various flat stones according to different sizes and thicknesses of the stone, the middle groove is polished, the edge groove is polished, the thickened straight edge is exposed to light, and the straight bottom edge is inverted at 45°C Corner, small R round belt side polishing, slot polishing, begonia angle back cut, saw blade seamless without back cutting, skirting line, anti-slip groove, French edge, straight edge, angular edge, etc. Shaped and polished, rough grinding, The fine grinding and polishing processes are completed at one time, the brightness after processing is higher than the bright cutting of the board surface, and the back cutting and bottom belt polishing are completed at one time.

| Features |

| Technical Parameters |

| Feed Output Speed | 1m-4m/min |

| The Minimum Processing Size of Stone | 10-100 mm x 50mm |

| Total Power | 50KW |

| Body Weight | 5500KG |

| Boundary Dimensions | 7800mm x 1400mm x 2000mm |

| Processing Photo |

| Dafon Company |

| Certificate Certification |

| After Sales Service |

We provide skilled and rich experience technicians for installation and after-sale service.

| Pre-Sales Service * Inquiry and consulting support. * Configure the best machine line according to customer condition * View our Factory. | After-Sales Service * Training on how to install the machine, training how to use the machine. * Engineers available to service machinery overseas. * Lifetime technology maintenance in free and spare parts supply. Related Products |

| Exhibition Show |

| Packaging & Shipping |

The machine will be consolidated tightly and safely within the container and delivered by sea or railway, we offer fast delivery and prompt reaction.

| FAQ |

Q: When can you ship my order?

A: Normally 15-20days after advanced payment is received. The exact delivery date will be advised after the order is confirmed. We will try our best to deliver soonest if you need them urgently.

Q: How long is the warranty period for the machine?

A: one year!

Q: How do I install and operate the machine, after receiving it?

A: For simple machines, we will provide sufficient installation, operation, and maintenance instructions, and videos, which will make the whole thing as simple as possible for users. For high-tech machines, our engineers can fly abroad to help you install & debug the machine, and teach you how to operate and maintain the machine properly in the future.

Q: Are you a manufacturer or trading company?

A: We are a manufacturer that has our own factory, technical Dept., marketing, and after-sale service teams.

Q: What is your advantage?

A: Firstly we are a manufacturer, you could get the best price without paying any commission. Secondly, we provide advisory machinery, debugging, maintenance, and fault-handling package services. Thirdly, we offer customized overall solutions and one-stop service. Both our machine and diamond tools are excellent. Fourthly, we give you technical support on not only machines but also diamond tools. Finally, better and lower cost after-sale service could be provided thanks to our worldwide network.