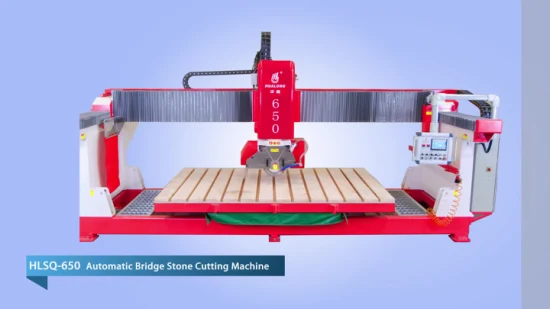

Hualong Factory Supply Low Price Bridge Saw Stone Cutting Machine with Siemens, Schneider Electric and Other High Quality Accesories Such as Hiwin Linear Guide

Basic Info

| Model NO. | HLSQ-650 |

| After-sales Service | Provided |

| Warranty | 1 Year |

| Type | Automatic Mono Bc |

| Usage | Ceramics, Granite, Marble |

| Application | Art & Craft, Stone Industry |

| Source Voltage | 380V |

| Automation | Automatic |

| Cutting Ability | High Speed |

| Control | Siemens PLC |

| Certification | ISO, CE |

| Color | Red and Ivory |

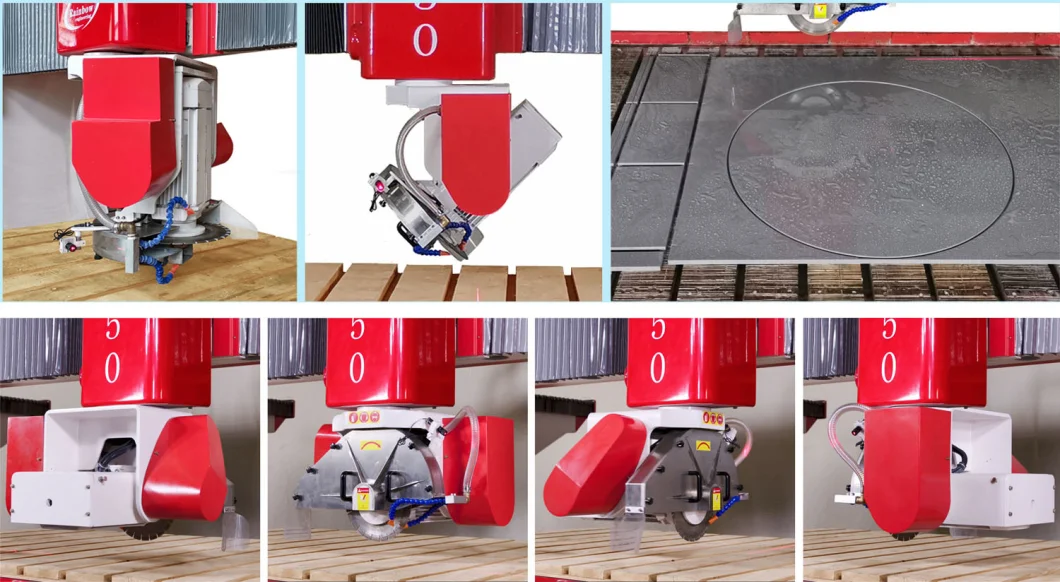

| Head Rotate 4 Positions | 0/90/180/270degree |

| Head Tilting Position | 45/90 Degree |

| Table Rotate | 0-360 Degree |

| Table Tilt | 0-85 Degree |

| Guide Rail | Hiwin Linear Guide |

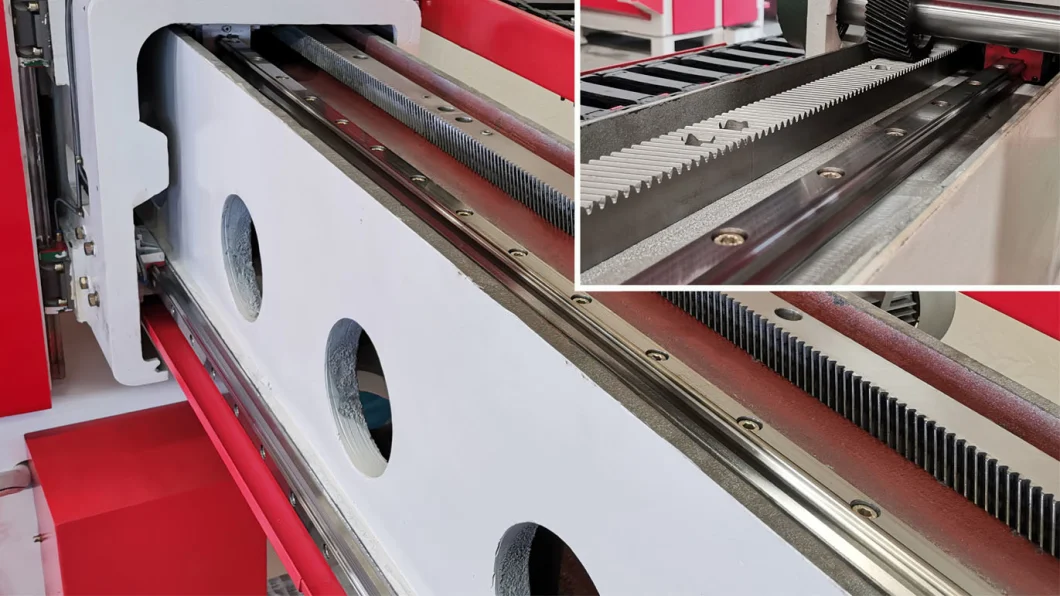

| Gearing | Rack Gear |

| Touch Screen | Siemens |

| Maximum Cutting Depth | 200mm |

| Main Elctric Components | Schneider and Siemens Brand |

| PLC | Siemens |

| Structure | Intergrated Machine |

| Machine Type | Mono Bridge Saw |

| Cutting | Automatically |

| Remoter | with Remoter Control |

| Transport Package | Plastic Packing |

| Specification | Working Area: 3300*2000mm |

| Trademark | Hualong |

| Origin | Putian, Fujian, China |

| HS Code | 84641010 |

| Production Capacity | 50 Pieces/Month |

Product Description

Hualong HLSQ-650 Stone bridge saw has a classic mono-block design which makes it quite compact as well as easy to install. This is a powerfull saw that allow you, through a Siemens controler with human-machine interface , simple to set up mutiple X and Y axis cuts, then process fine and easy. This is huge time saver and creates a highly efficient work atmosphere.

It is a classic and practical bridge stone cutting machine for cutting granite, marble, quartz and other stone slabs.

TECHNICAL DATA HLSQ-650 | |||

Configuration | Diameter of saw blade | mm | Φ400 - Φ650 |

Dimension of working platform | mm | 3300 x 2000 | |

Power of main motor | kw | 15 | |

Power of tool slide reciprocating motor | kw | 1.1 | |

Power of crossbeam shifting motor | kw | 1.5 | |

Power of hydraulic station motor | kw | 2.2 | |

Power of elevator motor | kw | 1.5 | |

Gross power | kw | 21.3 | |

Main Performance Parameters | Max. length of horizontal cutting | mm | 3300 |

Max. thickness of cutting | mm | 200 | |

Max. lifting travel of cutter | mm | 300 | |

Water consumption | m3/h | 2 | |

Measurement | Gross weight | kg | 5800 |

Dimension (L x W x H) | cm | 5750x3600x3400 | |

Main Features1) Monoblock structure for easy move, installation and no foundation needed.2) Siemens, Schneider electric and other high quality accesories such as Hiwin linear guide are adopted.3) 0°, 90°, 180° and 270° automtaic head rotatation and blade positioning. 4) Blade can tilt automatically 45° for chamfering cutting, or tilt 90° for milling.5) Automatic cross cutting repeatedly so easy by pushing one-button.6) Speed can be adjusted according to the stone material cutted.6) Automatic or manual working mode is optional.7) Worktable can rotate 0-360°, pause at every 45° automatically or lock at any degree by remote control.8) Worktable can tilt 0-85°, easy for slab loading.

Details Image

Control system

Brand: SiemensUse advanced PLC control system with touch screen to achieve multi programming methods, including manual programming or PC processing operation for powerful functions, which offer friendly and inteligent control.

Linear Guide

Brand: Hiwin

Original: Taiwan, China

Famous products, top quality used on crossbeam (X axis), carling (Y axis) and Z axis to gurantee perfect cutting accuracy and long lifespan.

Laser Reticule Apparatus

Origin: ChinaLaser checking and calibration instrument to aid in lining up the cut at the beginning of processing.

Other Advantages

1) 25 years + experience professional on making stone machines.2) Good performance and Long life service --- Our HLSQ series bridge saw was first exported to Brazil in 2012, which is still working well now.3) The machining operation is simpler than the operation of other infrared cutting machine, automatically cut by setting parameters.4) For chamfering cutting, the blade tilt of HLSQ-650 is controled by PLC, which cutting is accurate. While the other two ways as showed below, the cutting is less accurate, not good for cutting thin slab.

Application* Slab cutted to square size or other polygonal

* Round desktop processing

* Profiling Cutting (optional)

According to customer requirements, this machine can be equipped with profiling module to achieve profiling cutting function, used for processing special-shaped stone lines, decorating door frames, windows, columns and walls, etc.